Technical Performance at a Glance CETP UNNAO

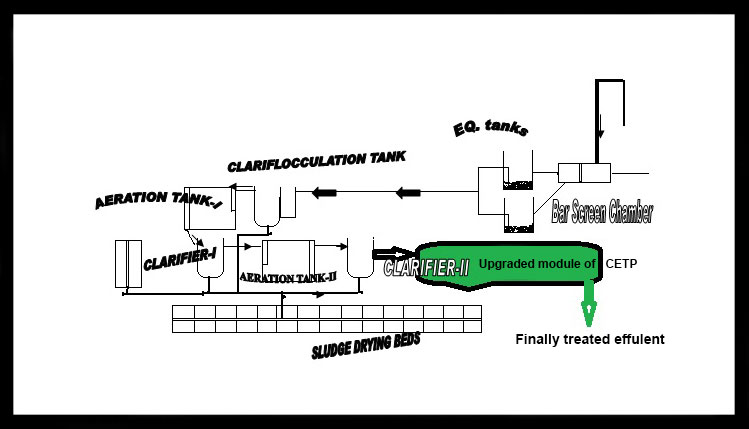

Green Portion in the diagram above shows the upgraded module of CETP Unnao discharging effluent into LONI DRAIN after enhanced and extended biological treatment of effluent from its old module.

Process Flow Pattern/stage-wise parameter reduction

Raw effluent Bar Screen EQ.

Tanks in parallel pH7-8, BOD-1000-1200, COD-2000-3000, SS-2000-3000, TDS-5000-10000

Clariflocculation Tank pH7-8,BOD-700-900,COD-1500-2100,SS-600-1200, ,TDS-5000to 10000

Aeration Tank I Clarifier First stage pH7.5-7.8,BOD-400-500,COD700-1000

Aeration Tank II Clarifier II V-Notch for final discharge pH 7-7.5,BOD 20-60, COD-160-240,TDS-5000-10000,SS-60-120 mg/l.

Input to New Module which gives final outlet for disposal into LONI DRAIN having TSS<10 mg/l, COD<180 mg/l, BOD<10 mg/l & Cr<0.01 mg/l.All values except pH are in mg/l.

UPPCB’S CROSS VERIFICATION OF PLANT’S OPERATIONAL CONTINUTITY FROM POWER CONSUMPTION AT CETP VIS-À-VIS ITS CONNECTED LOAD AND PRESENT EFFLUENT LOAD BEING DISCHARGED BY ITS MEMBER INDUSTRIES:

Connected load at CETP = 150 KVA + 200 KVA ( New upgradation module)=350 KVA

CETP Capacity = 2150 KL/day, upgraded module under operation as enhanced treatment is series.

Available effluent load = Avg 2100 Kl/day to 2400 Klday(The excess effulent to the tune of approx 500 Kl/day is being discharged into CETP by defaulter tanneryIQbal Leather Ltd.)

Average expenditure at CETP : Month

Rs 10 lakh which includes majorily for electric power & Diesel fuel for back power. Rest include Sludge disposal, O&M, salary & wages, Oil & Lubricants and electric & Mechanical maintenance, plant insurance etc.